Basalt Fiber Chopped Strands For Thermoplastic

PRODUCT INTRODUCTION

Basalt fiber chopped strands for thermoplastic composites have gained significant attention in recent years due to their exceptional properties and numerous advantages over traditional reinforcement materials. This innovative material is derived from natural basalt rock and is processed into fine strands, making it an ideal choice for enhancing the performance of thermoplastic composites in various applications.

One of the primary reasons why basalt fiber chopped strands are preferred for thermoplastic composites is their remarkable strength and stiffness. Basalt fibers exhibit high tensile strength and modulus, making them an excellent reinforcement material for thermoplastics. This results in composites with enhanced mechanical properties, including improved impact resistance and durability, making them suitable for demanding applications in industries such as automotive, construction, and aerospace.

Furthermore, basalt fiber chopped strands offer superior resistance to chemical and environmental degradation. Unlike traditional reinforcement materials like glass fibers, basalt fibers are highly resistant to alkalis, acids, and corrosive environments, making them an ideal choice for applications where exposure to harsh chemicals or outdoor elements is a concern. This exceptional resistance contributes to the longevity and reliability of thermoplastic composites reinforced with basalt fibers.

In addition to their mechanical and chemical properties, basalt fiber chopped strands are also known for their thermal stability. These fibers can withstand high temperatures without significant loss of strength or stiffness, making them suitable for applications that require resistance to heat and fire. This thermal stability makes basalt fiber chopped strands an excellent choice for thermoplastic composites used in high-temperature environments or in applications where fire safety is a priority.

Moreover, basalt fiber chopped strands are environmentally friendly and sustainable. As a natural material, basalt rock is abundant and widely available, and the manufacturing process for basalt fibers consumes less energy compared to other synthetic fibers. This makes basalt fiber chopped strands a more eco-friendly choice for reinforcing thermoplastic composites, aligning with the growing emphasis on sustainability in the materials industry.

In conclusion, the numerous advantages of basalt fiber chopped strands make them a superior choice for reinforcing thermoplastic composites. Their exceptional strength, chemical resistance, thermal stability, and environmental sustainability position them as a highly desirable reinforcement material for a wide range of applications. As industries continue to seek high-performance and sustainable materials, basalt fiber chopped strands for thermoplastic composites are poised to play a pivotal role in shaping the future of composite materials.

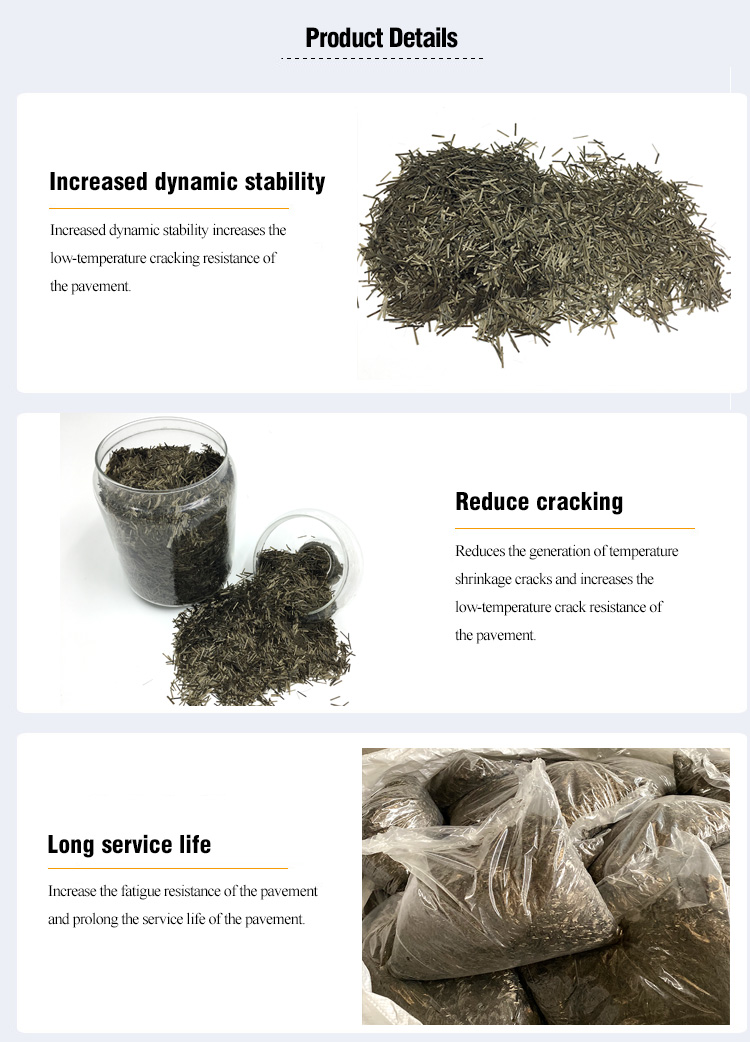

PRODUCT FEATURES

1. Good combination with resin, good enhancement effect

2. Less hairiness of the product

3. Good dispersion during extrusion

4. Good temperature resistance

5. Making dark-colored products

PRODUCT SPECIFICATION

|

Example |

702.B2.13-6 |

|

Type of Size |

Silane |

|

Size Code |

B2 |

|

Chop length (mm) |

3/4.5/6 |

|

Filament (μm) |

10/11/13 |

APPLICATIONS

PACKING

|

(mm ) Length (in) |

950 (37.4 ) |

|

(mm ) Wide (in) |

950 ( 37.4 ) |

|

(mm ) Hight (in) |

1000(39.4) |

|

(kg ) Weight (lb ) |

900-1000 ( 1984-2205) |

Baslt Fiber products should be stored in a dry,cool and moisture-proof area, and they should remain in their original package until prior to use.