Basalt fibre geogrids offer many advantages in replacing reinforcing steel mesh

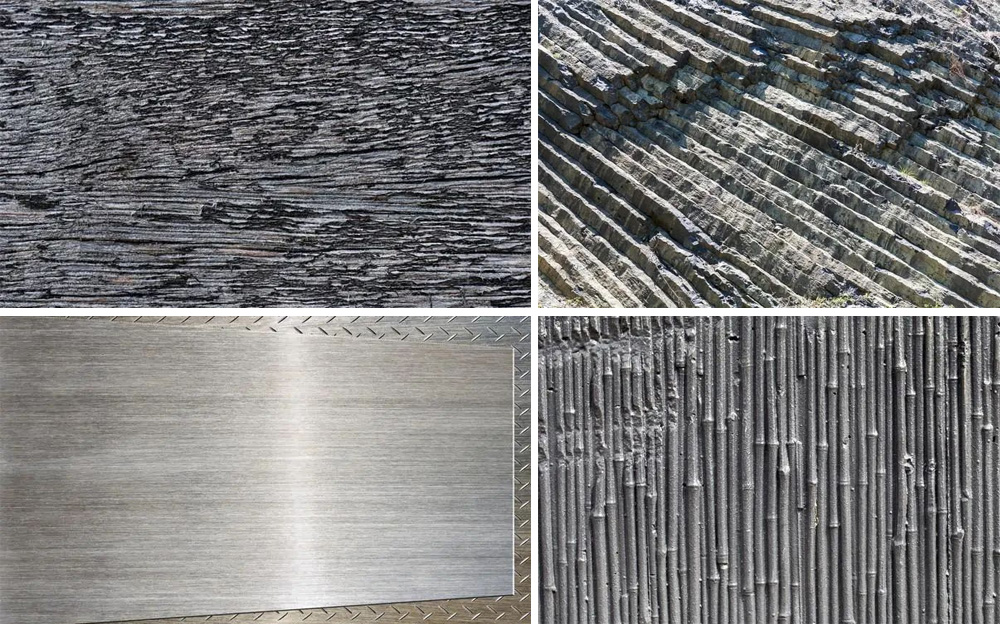

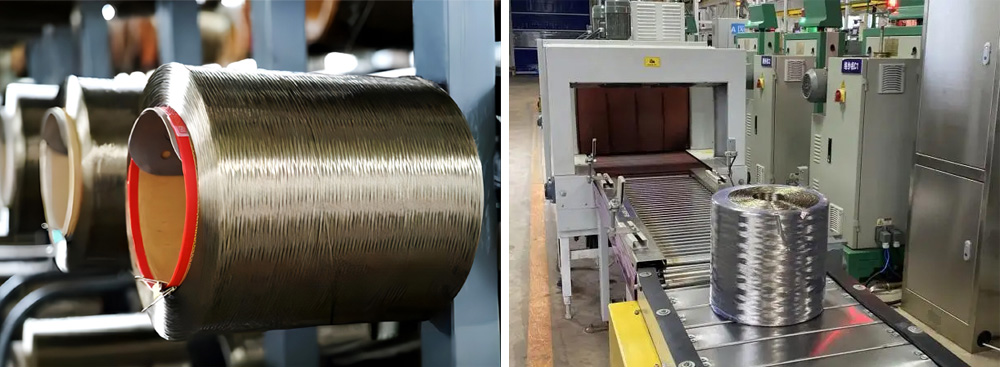

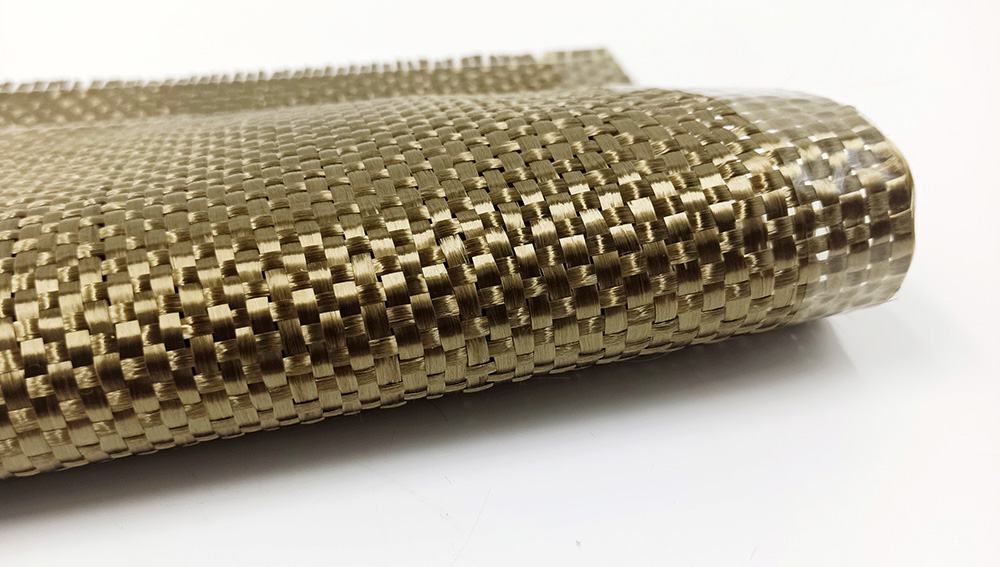

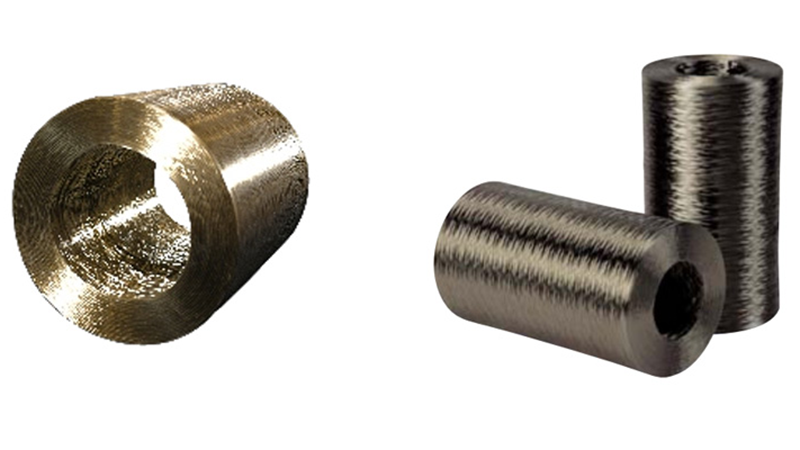

Basalt fibre geogrid is a kind of mesh reinforced product produced by basalt fibre material. It has good alkali resistance, flexibility and high tensile strength in the warp and weft directions, belongs to the non-metallic inorganic fibre, presents golden brown colour, and has the characteristics of non-combustible, non-toxic and environmentally friendly (low carbon material). In addition, basalt fibre geogrid also has the advantages of freezing and thawing (-260-650 ℃), the same coefficient of thermal expansion as asphalt concrete, high tensile strength, UV protection, chemical resistance and stability, thus making it has a wide range of prospects for application in the field of roads, bridges, buildings and so on.

In contrast, reinforcing mesh, as a traditional building reinforcement material, has limitations in some aspects, although it has the properties of high strength, corrosion resistance and fatigue resistance. For example, reinforcing mesh is susceptible to corrosion, which reduces its strength and durability; at the same time, reinforcing mesh also suffers from installation difficulties and higher costs during construction.

Basalt fibre geogrids have many advantages in replacing reinforcing mesh. First of all, the impact resistance and seismic performance of basalt fibre is better than that of steel reinforcement in occasions with frequent impact or vibration. This means that in some special projects or earthquake-prone areas, basalt fibre geogrid can be used as an effective alternative material to improve the stability and safety of the structure.

Secondly, in terms of corrosion resistance, basalt fibre geogrid has significant advantages. Since it is an inorganic fibre, it is almost unaffected by seawater, acid and alkali and other external environments, so it has high corrosion resistance. This makes the basalt fibre geogrid able to keep its performance stable for a long time in highly corrosive environments such as seashores and chemical plants, prolonging the service life of the structure.

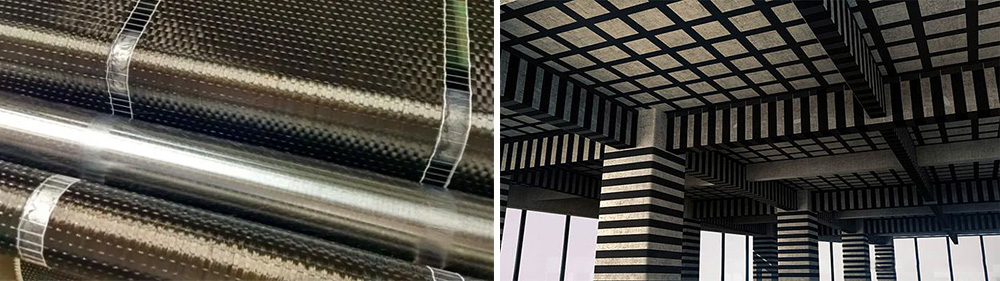

In addition, basalt fibre geogrids have excellent construction properties. Its surface is coated with PVC and dried, which increases the adhesion with the asphalt surface layer and improves the performance of the product. At the same time, the installation process of basalt fibre geogrid is relatively simple, which can greatly shorten the construction period and reduce construction costs.

In practical application, basalt fibre geogrid has successfully replaced some of the steel mesh application scenarios. For example, in the road reconstruction and widening of new and old pavement splicing joints anti-cracking, the old cement and asphalt concrete pavement paving anti-cracking, new inorganic combination of granular material grass-roots level pre-cutting joints anti-cracking as well as waterproofing of bridge decks anti-cracking and so on, the basalt fibre geogrids have demonstrated a good performance. At the same time, in the construction field, basalt fibre geogrid is also widely used in wall reinforcement, fire prevention, heat preservation, etc., for the stability of the building structure and safety provides a strong guarantee.

In summary, basalt fibre geogrid, as a new type of building reinforcement material, has a wide range of application prospects and significant advantages in replacing reinforcing steel mesh. With the continuous progress of science and technology and the increasing demand for new materials in the construction industry, it is believed that basalt fibre geogrid will be more widely used and promoted in the future, injecting new vitality into the development of the construction industry.